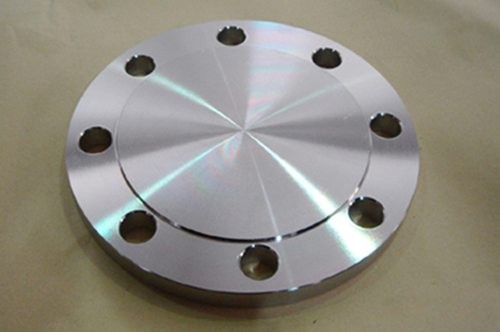

Blind Flange

Flange blind plate

I. product introduction

Flange flange, also known as blind flange, real name blind flange. Is a form of connection for flanges. It's a flange without a hole in the middle. One of its functions is to seal up the end of the pipe, and the other is to facilitate the removal of debris in the pipe during maintenance. In terms of sealing effect, it has the same effect as the head and the cap. But there is no way to remove the head, and the flange blind plate is fixed with bolts, it is very convenient to remove. Flange blind plate material has carbon steel, alloy steel, stainless steel, plastic and so on.

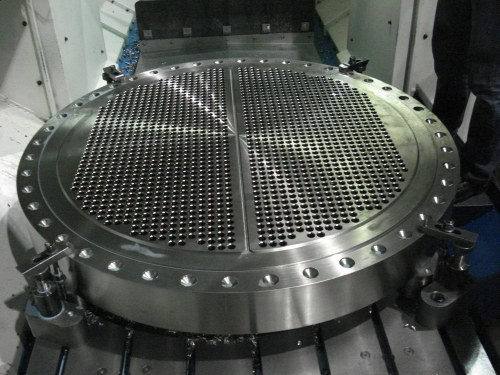

Ii. Product parameters

Iii. Product advantages

Flange blind plate is mainly used to completely isolate the production medium to prevent the production from being affected or even causing accidents due to the loose closing of the cut-off valve. Flange blind plate should be set in the place where isolation is required, such as the device nozzle, before and after the cut-off valve or between two flanges. Insert plate (round blind plate) can be used for pressing, blowing and other disposable parts. The function is the same as that of the head and cap, except that the blind seal is a detachable seal and the head seal is not ready to be opened again. There are many types of sealing surface, including plane, convex surface, concave and convex surface, tenon groove surface and ring connecting surface. Materials are carbon steel, stainless steel, alloy steel, copper, aluminum, PVC and PPR. Production process is generally divided into four: forging, casting, plate cutting, casting. Among them, forging products have the highest price, followed by medium plate and the lowest casting and forging. Casting is the most secondary process. And the quality is forging and medium plate of good, cast forging of want a little bit poorer.

When the device is multi-series, the external main pipeline from the boundary area is divided into several sub-channels into each series, and the blind plate flange is arranged at the cut-off valve of each sub-channel. When the process pipeline of charging pipeline and replacement gas pipeline (such as nitrogen pipeline and compressed air pipeline) is connected with the equipment, the blind plate flange shall be set at the cut-off valve. The exhaust pipe, drain pipe and sampling pipe of equipment and pipeline shall be equipped with blind flange or wire plug behind the valve. Non-toxic, non-hazardous and non-explosive materials are excluded.

When the device is constructed in stages, when the interconnecting device is constructed in stages, the connecting pipeline shall set the blind flange at the cut-off valve to facilitate the subsequent construction. When the device is in normal production, for some auxiliary pipelines that need to be cut off completely, blind plate system pipeline should be set and blind plate flange should be set at the cut off valve to facilitate the subsequent construction.

Flange blind plate

I. product introduction

Flange flange, also known as blind flange, real name blind flange. Is a form of connection for flanges. It's a flange without a hole in the middle. One of its functions is to seal up the end of the pipe, and the other is to facilitate the removal of debris in the pipe during maintenance. In terms of sealing effect, it has the same effect as the head and the cap. But there is no way to remove the head, and the flange blind plate is fixed with bolts, it is very convenient to remove. Flange blind plate material has carbon steel, alloy steel, stainless steel, plastic and so on.

Ii. Product parameters

Iii. Product advantages

Flange blind plate is mainly used to completely isolate the production medium to prevent the production from being affected or even causing accidents due to the loose closing of the cut-off valve. Flange blind plate should be set in the place where isolation is required, such as the device nozzle, before and after the cut-off valve or between two flanges. Insert plate (round blind plate) can be used for pressing, blowing and other disposable parts. The function is the same as that of the head and cap, except that the blind seal is a detachable seal and the head seal is not ready to be opened again. There are many types of sealing surface, including plane, convex surface, concave and convex surface, tenon groove surface and ring connecting surface. Materials are carbon steel, stainless steel, alloy steel, copper, aluminum, PVC and PPR. Production process is generally divided into four: forging, casting, plate cutting, casting. Among them, forging products have the highest price, followed by medium plate and the lowest casting and forging. Casting is the most secondary process. And the quality is forging and medium plate of good, cast forging of want a little bit poorer.

When the device is multi-series, the external main pipeline from the boundary area is divided into several sub-channels into each series, and the blind plate flange is arranged at the cut-off valve of each sub-channel. When the process pipeline of charging pipeline and replacement gas pipeline (such as nitrogen pipeline and compressed air pipeline) is connected with the equipment, the blind plate flange shall be set at the cut-off valve. The exhaust pipe, drain pipe and sampling pipe of equipment and pipeline shall be equipped with blind flange or wire plug behind the valve. Non-toxic, non-hazardous and non-explosive materials are excluded.

When the device is constructed in stages, when the interconnecting device is constructed in stages, the connecting pipeline shall set the blind flange at the cut-off valve to facilitate the subsequent construction. When the device is in normal production, for some auxiliary pipelines that need to be cut off completely, blind plate system pipeline should be set and blind plate flange should be set at the cut off valve to facilitate the subsequent construction.