-

Fire Tee

Tee is also known as tee or tee pipe fitting, tee joint, etc.Mainly used to change the direction of the fluid, used in the main pipe to the branch pipe.It can be classified by diameter.It is generally made of carbon steel, cast steel, alloy steel, stainless steel, copper, aluminum alloy, plastic, argon mold, PVC and other materials.

Send Email Details

The tee is a pipe fitting and pipe connection.Also called pipe fitting tee or tee pipe fitting, stainless steel equal diameter tee tee connector, used in the main pipe to branch pipe.

Three - way is with three openings, namely an import, two exports;Or a kind of chemical pipe fitting with two inlet and one outlet, having a T and Y shape, an equal diameter pipe mouth, and a reducing pipe mouth, used for the convergence of three same or different pipes.The main function of the tee is to change the direction of the fluid.

According to the size of pipe diameter

1. The nozzle ends of equal diameter tees are of the same size;

2. The pipe pipe size of the reducing tee is the same, while the pipe pipe size of the branch pipe is smaller than the pipe size of the pipe.

By process

1. Hydraulic bulging

The hydraulic bulging of three - way is a forming technology which compensates the bulging branch pipe by the axial direction of metal material.The process is to use special hydraulic press, with three links within the tube billet diameter equal injection liquid, through the two horizontal side of the hydraulic cylinder synchronization of the motion of tube billet, billet after squeezed smaller volume, smaller volume of liquid with the tube billet inside the tube billet and pressure, when pressure tee branch pipe bulge out to the metal material in the liquid in the cylinder and the pipe pressure under the dual role of flow along the mold cavity and the branch pipe.

Three - way hydraulic bulging process can be formed once, high production efficiency;The main pipe and shoulder wall thickness have increased.

Due to the large tonnage of equipment required for seamless tee bulging process, it is mainly used for the manufacture of tee with standard wall thickness less than DN400 in China.The suitable forming materials are low carbon steel, low alloy steel and stainless steel with relatively low hardening tendency, including some nonferrous materials, such as copper, aluminum and titanium.

2. Hot pressing

Hot pressing of tee is to flatten the pipe billet larger than tee diameter to the size of tee diameter, and then make a hole in the drawing branch pipe of cold drawing tee.The tube billet is heated, put into the forming die, and in the tube billet is loaded with the drawing die;Under the action of pressure, the tube billet is compressed radially. In the process of radial compression, the metal flows towards the direction of the branch pipe and forms the branch pipe under the drawing of the die.The whole process is formed by the radial compression of the tube billet and the drawing of the branch tube.Different from the hydraulic bulging tee, the metal of the hot-pressed tee branch pipe is compensated by the radial movement of the pipe billet, so it is also called radial compensation process.

Due to the use of heating pressing tee, the material forming equipment tonnage is reduced.Hot pressing tee has a wide adaptability to materials, suitable for low carbon steel, alloy steel, stainless steel materials;In particular, large diameter and wall thickness of the tee, usually used this forming process.

By material

Carbon steel, cast steel, alloy steel, stainless steel, copper, aluminum alloy, plastic, argon mold, PVC, etc.

Divided by production method

Top, pressing, forging, casting, etc.

By manufacturing standards

GB/ t12459-2005,GB/ t13401-2005,ASME B16.9,SH3408, sh3409-96, sh3410-96,HG/T21635,DL/T 695,SY/T 0510,DIN 2615.

-

Stone Fire Tube

Four - way for pipe fitting, pipe connector.Also called pipe fitting four or four - way pipe fitting, four - way joint, used in the main pipe to branch pipe.

Send Email Details

The four passes are divided into equal diameter and reducing diameter. The pipe ends of the four passes are of the same size.The pipe size of the four - way pipe is the same, while the pipe size of the branch pipe is smaller than the pipe size of the pipe.A four - way is a pipe fitting for pipe branches.

Folding hydraulic bulging

Four-way hydraulic bulging is a forming process of expanding branch pipe by axial compensation of metal material.The process is to use special hydraulic press, will be equal and cross welding cross diameter of tube billet inside the injection liquid, through the two horizontal side of the hydraulic cylinder synchronization of the motion of tube billet, billet after squeezed smaller volume, smaller volume of liquid with the tube billet inside the tube billet and the pressure increases, when the four-way pipe bulge out to the pressure, the metal material in the liquid in the cylinder and the pipe pressure under the dual role of flow along the mold cavity and the branch pipe.Four - way hydraulic bulging process can be formed in one time, high production efficiency;There was an increase in the wall thickness of the main part and the shoulders.Due to the large tonnage of equipment required for seamless four-way hydraulic bulging process, it is mainly used for four-way manufacturing of standard wall thickness less than DN400 in China.The suitable forming materials are low carbon steel, low alloy steel and stainless steel with relatively low hardening tendency, including some nonferrous materials, such as copper, aluminum and titanium.

Folding and hot pressing

Four-way hot pressing is to flatten the tube billet which is larger than the four-way diameter to the size of the four-way diameter, and open a hole in the part of the stretching branch pipe.The tube billet is heated, put into the forming die, and in the tube billet is loaded with the drawing die;Under the action of pressure, the tube billet is compressed radially. In the process of radial compression, the metal flows towards the direction of the branch pipe and forms the branch pipe under the drawing of the die.The whole process is formed by the radial compression of the tube billet and the drawing of the branch tube.Different from the hydraulic bulging four-way, the metal of the hot-pressed four-way branch pipe is compensated by the radial movement of the tube billet, so it is also called radial compensation process.

Due to the use of heating after pressing the four - way, the material forming equipment tonnage is reduced.The hot-pressed four-pass has a wide adaptability to materials, suitable for low carbon steel, alloy steel, stainless steel materials;In particular, large diameter and wall thickness of the four - way, usually used this forming process.

1. Carbon steel, cast steel, alloy steel, stainless steel, copper, aluminum alloy, plastic, argon mold, PVC, etc.

2. According to the production method, it can be divided into top, pressing, forging, casting, etc.

3. To make standard classification can be divided into the national standard, the electric standard, water standard, American standard, Germany standard, Japanese standard, the standard, etc., specific as follows: GB/T12459, GB/T13401, ASME B16.9, SH3408, SH3409, HG/T21635, DL/T 695, SY/T 0510, DIN 2615 -

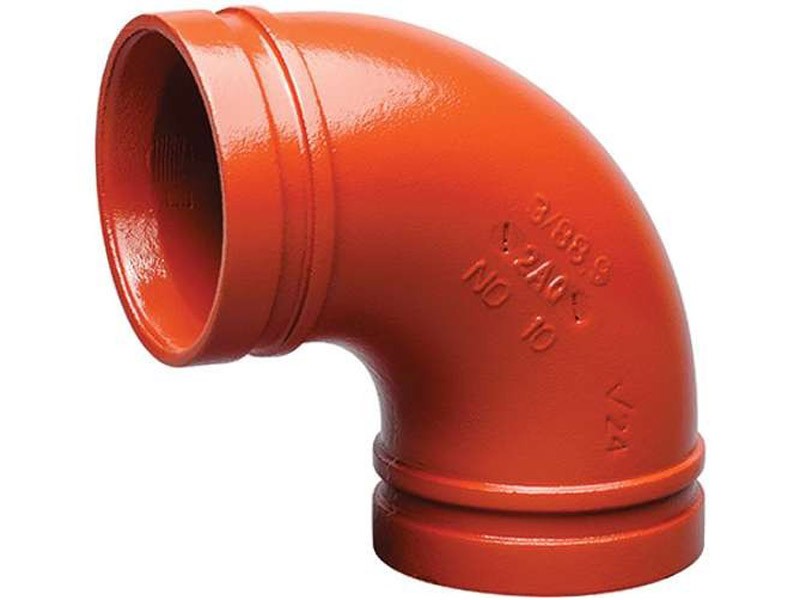

Elbow For Fire Pipe Fittings

Elbow is a pipe fitting that changes the direction of the line.According to the Angle, there are 45° and 90°180° three most commonly used, in addition, according to the engineering needs to include 60° and other abnormal Angle bend.Elbow materials are cast iron, stainless steel, alloy steel, malleable iron, carbon steel, nonferrous metals and plastics.The method of connection with pipe is: direct welding (the most common way) flange connection, hot welding connection, electric welding connection, threaded connection and socket connection.According to the production process can be divided into: welding elbow, stamping elbow, push bending, casting elbow, butt welding elbow.Other names :90 degree bend, right Angle bend, love bend, etc.Elbow is a kind of pipe fitting commonly used in plumbing installation. It is used to connect the pipe at the bend and change the direction of the pipe.

Send Email Details

Other names :90° bend, right Angle bend, love bend, stamping bend, pressing bend, mechanism bend, welding bend, etc.

Purpose: connect two pipes with the same or different nominal sizes to make the pipe turn at 90°, 45°, 180° and various degrees.

Bending radius less than or equal to 1.5 times of the pipe diameter belongs to the elbow, greater than 1.5 times of the pipe diameter belongs to the elbow.

A pipe fitting commonly used in pipeline installation is used to connect two pipes of the same or different nominal sizes to make the pipe turn at a certain Angle and the nominal pressure is 1-1.6mpa.

1. As most of the pipe fittings are used for welding, in order to improve the welding quality, the ends are turned into a groove, with a certain Angle and a certain edge. This requirement is also strict.The surface quality and mechanical properties are basically the same as the pipe.For the convenience of welding, the pipe fitting is of the same type of steel as the pipe being connected.

2, is that all the pipe fittings have to go through the surface treatment, the inside and outside of the surface of the iron oxide through peening treatment spray off, and then coated with anti-corrosion paint.This is for export needs, moreover, in the domestic is also to facilitate transportation to prevent corrosion and oxidation, we should do this work.

3, it is to the requirement of packing for small pipe fitting, such as export, you need to make a wooden case, about 1 cubic meter, the number of elbow in this kind of box is about not more than a ton, the standard allows a suit, namely big set small, but the total weight is generally not more than 1 ton.For large pieces y you need a single package, like 24 "you need a single package.Additional it is packing mark, mark is to want to indicate dimension, steel number, batch number, manufacturer trademark to wait.

Fold by material

Carbon steel: ASTM/ASME A234 WPB, WPC

Alloy: ASTM/ASME A234 WP 1-wp 12-wp 11-wp 22-wp 5-wp 91-wp911, 15Mo3 15CrMoV, 35CrMoV

Stainless steel :ASTM/ASME A403 WP 304-304l-304h-304ln -304N

ASTM/ASME A403 WP 316-316 l - 316 - h - 316 ln - 316 - n - 316 ti

ASTM/ASME A403 WP 321-321h ASTM/ASME A403 WP 347-347h

Low temperature steel :ASTM/ASME A402 wpl3-wpl 6

High performance steel: ASTM/ASME A860 WPHY 42-46-52-60-65-70

Cast steel, alloy steel, stainless steel, copper, aluminum alloy, plastic, argon mold, PVC, PPR, RFPP, etc.

1. According to the production method, it can be divided into pushing, pressing, forging, casting, etc.

2. According to the manufacturing standard, it can be divided into national standard, electric standard, ship standard, chemical standard, water standard, American standard, German standard, Japanese standard and Russian standard.

3. According to its radius of curvature, it can be divided into long radius elbow and short radius elbow.Long radius elbow refers to the outer diameter of the pipe whose radius of curvature is equal to 1.5 times, that is, R=1.5D;Short radius elbow means that its radius of curvature is equal to the outer diameter of the pipe, that is, R= 1.0d.(D is the diameter of the elbow, and R is the radius of curvature).

4. According to the pressure levels, there are about 17 types, which are the same as the American pipe standards, including Sch5s, Sch10s, Sch10, Sch20, Sch30, Sch40s, STD, Sch40, Sch60, Sch80s and XS.Sch80, SCH100, Sch120, Sch140, Sch160, XXS;The two most commonly used are STD and XS.

5. According to the different shapes of the purposes can be divided into: groove bend, sleeve bend, double bearing bend, flange bend, reducing bend, stand bend, internal and external tooth bend, stamping bend, push bend, socket bend, butt welding bend, inner wire bend, etc.

Folding routine classification

Flexible elbow clip sleeve elbow with edge quick installation elbow with seat elbow flange elbow 180° double bearing elbow single bearing elbow

Socket elbow reducing elbow seamless elbow butt welding elbow 90° elbow 45° elbow combination tee internal thread elbow stamping elbow, push elbow, high pressure elbow wear-resisting elbow, mechanical elbow flange elbow groove elbow elbow thread elbow special elbow waterproof elbow -

Fire Reducing Pipe

Reducing pipe is a kind of pipe fitting which is used for pipe tapering. Usually, the forming process is reducing diameter pressing, expanding diameter pressing or reducing diameter pressing plus expanding diameter pressing.

Send Email Details

In addition to using steel pipe as raw material to produce reducing pipe, some reducing pipes of specifications can also be produced by using steel plate stamping forming process. The shape of the punching die used for drawing is designed according to the surface size of the reducing pipe, and the steel plate after blanking is pressed and stretched into shape with the punching die.

A closed loop of pipe connections.It is mainly used for oil and gas gathering and transportation networks in oil and gas fields, water supply and gas distribution networks in cities, etc.The reliability of the pipeline is higher than that of the branch pipe network, and the future transmission will not be interrupted due to a fault, but the total length of the pipeline has been increased.At each node of the pipe network, the outflow volume is equal to the flow volume.Reducing pipe (size head) is a type of pipe fitting used at pipe sizing.The usual forming process is reducing diameter pressing, expanding diameter pressing or reducing diameter plus expanding diameter pressing.

1. Reduced/expanded diameter forming

The reducing diameter forming process of reducing pipe is to put the pipe blank with the same diameter as the big end of the reducing pipe into the forming die and press along the axial direction of the pipe blank to make the metal move along the die cavity and shrink forming.According to the size of reducing pipe, it can be divided into one pressing forming or several pressing forming.The following figure is the drawing diagram of concentric reducer.

Expanding diameter forming is the tube billet with the diameter smaller than the big end diameter of the reducing pipe, and the tube billet is formed by expanding the diameter along the inner diameter of the tube billet with the inner die.The expanding process mainly solves the problem that the reducing pipe with large diameter is not easy to be formed by reducing diameter.

In the process of reducing or expanding the diameter, according to different materials and changing the diameter, the cold or hot pressing is adopted.Under normal circumstances, as far as possible to use cold pressure, but for many times to change the diameter and cause serious work hardening, wall thickness thick or alloy steel materials should be used hot pressure.

1. Stamping

In addition to using steel pipe as raw material to produce reducing pipe, for some specifications of reducing pipe can also be produced by steel plate using stamping forming process.The shape of the drawing die is designed according to the surface size of the reducing tube.

Folding structure characteristics

The reducing pipe is made of carbon steel and alloy steel. The stainless steel is represented by the large diameter multiplied by the small diameter multiplied by the thickness.

Reducing pipe standard: national standard American standard British standard and a variety of non-standard high pressure stamping.

The reducing diameter forming process of the reducing pipe is to put the tube blank with the diameter equal to the big end of the reducing pipe into the forming die, and through pressing along the axial direction of the pipe blank, make the metal move along the die cavity and contract forming. According to the size of the reducing pipe, it can be divided into one pressing forming or multiple pressing forming.

The characteristics of reducing pipe are that the strength is significantly higher than that of carbon steel with the same amount of carbon.

Fold the application

1. When the flow rate of the fluid in the pipeline changes, such as increasing or decreasing, and the flow rate requirements change little, the reducer shall be used.

2. At the entrance of the pump, reducing pipe is needed to prevent cavitation.

3, with the instrument, such as the flow meter, regulating valve joint, in order to cooperate with the instrument joint, also need to use reducing pipe.